Unlock the Editor’s Digest for free

Roula Khalaf, Editor of the FT, selects her favourite stories in this weekly newsletter.

Tufan Erginbilgiç threw his weight behind the decarbonisation of aviation last month. The Rolls-Royce boss will, however, end the company’s electric and hydrogen propulsion efforts. Erginbilgiç thinks the sector’s more immediate lower carbon future will come from sustainable aviation fuel.

The high cost of producing enough SAF is just one of the barriers that still needs to be overcome.

SAF makes sense for a new chief executive who is more concerned with cash flows than carbon dioxide. It is largely compatible with current engine technology, which reduces investment costs for manufacturers. Electric and hydrogen propulsion need hefty development to have any chance of overcoming low energy densities.

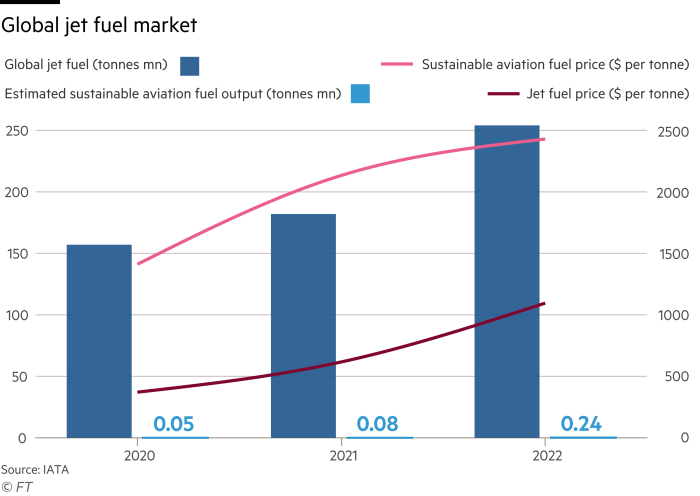

SAF currently accounts for a tiny proportion of global aviation fuel, about 0.1 per cent last year according to the International Air Transport Association. Production mostly involves converting waste fats and oils. This reduces net carbon emissions about 70 per cent compared to fossil jet fuels.

SAF is more than twice as expensive. Availability of feed stocks places limits on commercialisation. Power-to-liquid synthetics are a likelier solution. These “efuels” are made by combining hydrogen and carbon dioxide.

There is a catch. To achieve a 90 per cent lower carbon footprint for efuel compared to kerosene, hydrogen must be made from renewable sources as well. Carbon dioxide can be captured from existing industrial processes or directly from the atmosphere.

The technology remains years away from commercialisation. But it has industry backing. Rolls-Royce, Boeing and United Airlines are some of the companies putting money into start-ups. One of these, OXCCU, has also won UK government funding. Large renewable energy resources could make the UK an important producer in years to come.

But large investments are needed to get costs down. Currently, SAF is more than twice the price of conventional fossil jet fuel at as much as $1,500 a tonne. Power-to-liquid synthetics today cost as much as $5,500 per tonne, estimates Professor Mohamed Pourkashanian, head of the Energy Institute at the University of Sheffield.

He thinks that by 2030 they may account for up to 40 per cent of total SAF available, which the UK hopes will make up about a tenth of total fuel. That seems optimistic, given low current availability of green hydrogen. The positive is that the industry appears committed to the long haul.

If you are a subscriber and would like to receive alerts when Lex articles are published, just click the button “Add to myFT”, which appears at the top of this page above the headline.